Sep 14, 2025

Sep 14, 2025

258

258

admin

admin

12 Types of CNC Machines: Which One Is Right for You?

CNC machines are modern subtractive manufacturing equipment that automate tool paths and movements to remove material. Various types of CNC machines are used in industrial factories and workshops, each designed for specific manufacturing purposes. All operate by interpreting G and M codes to transform raw workpieces into finished parts.

Understanding the capabilities, advantages, limitations, and applications of different CNC machines can help you determine which machine—or combination—best meets your production needs.

Continue reading to explore 12 common CNC machine types, along with a brief guide on selecting the right one for your project.

What is a CNC Machine?

A CNC machine is a computerized manufacturing system that automatically removes material to shape a workpiece according to a digital design. Instead of manual operation, G and M codes control the movement of the spindle and axes. Tool positioning, alignment, speed, feed rate, and other variables are fully automated.

CNC integration enables faster production, higher accuracy, compatibility with multiple tools, and superior surface finishes.

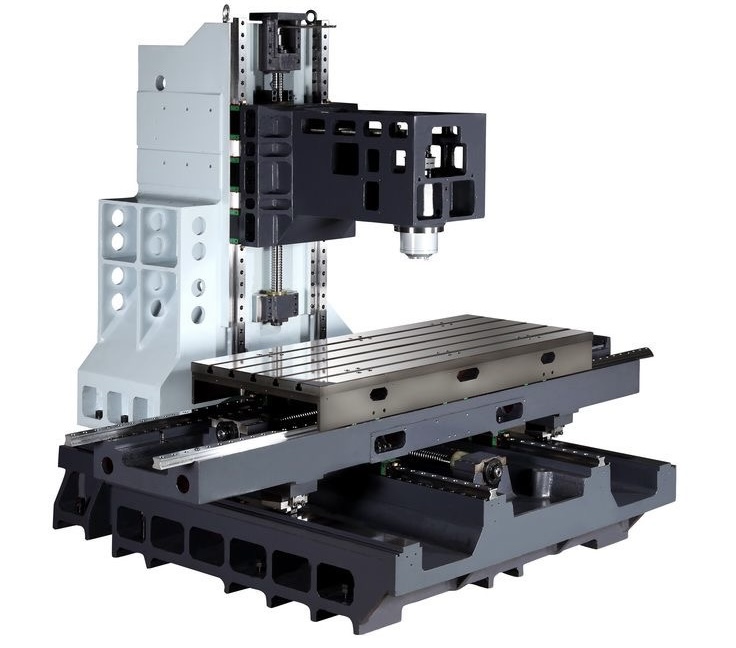

1. CNC Milling Machine

Milling machines are among the most common CNC equipment. They use multi-point rotating cutting tools attached to a CNC-controlled spindle, which moves across multiple axes (3, 5, or more) to remove material.

Common types include vertical and horizontal mills. Horizontal mills align the cutter parallel to the workpiece; vertical mills position it perpendicularly. Other varieties include manual, universal, and turret mills.

CNC mills can perform cutting, facing, reaming, drilling, chamfering, tapping, and more.

Capabilities

Supports various cutters: end mills, face mills, fly cutters, taps, reamers, etc.

Suitable for complex shapes and custom multi-axis machining.

Capable of machining large, heavy parts.

Limitations

Workpiece size limited by spindle flexibility and tool travel.

Potential backlash errors from lead screws and nuts.

Applications

Converting flat stock into complex shapes and profiles.

Rapid prototyping for automotive, aerospace, medical, and industrial sectors.

Production of automotive and custom mechanical parts.

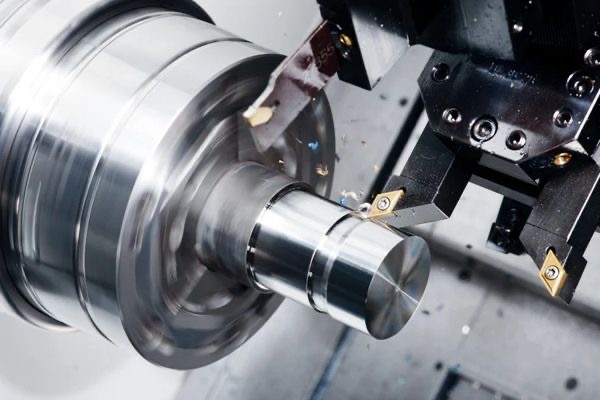

2. CNC Lathe

Lathes and turning centers produce axisymmetric parts such as cones, shafts, and cylinders. A stationary tool mounted on a turret feeds into a rotating bar to shape the material.

Common types include horizontal, vertical, slant-bed, multi-axis, and Swiss-style lathes. Each is suited to specific turning operations.

CNC lathes perform facing, turning, cutting-off, drilling, threading, knurling, tapering, chamfering, and boring.

Capabilities

High precision and repeatability for symmetrical shapes.

Faster cutting speeds and ability to process hard materials.

More compact than milling machines.

Limitations

Limited to cylindrical parts.

Requires skilled operators.

High initial setup and tooling costs.

Applications

Automotive suspension parts, frames, gears, engine components.

Custom hollow cylindrical parts with internal features.

Mechanical and tooling components.

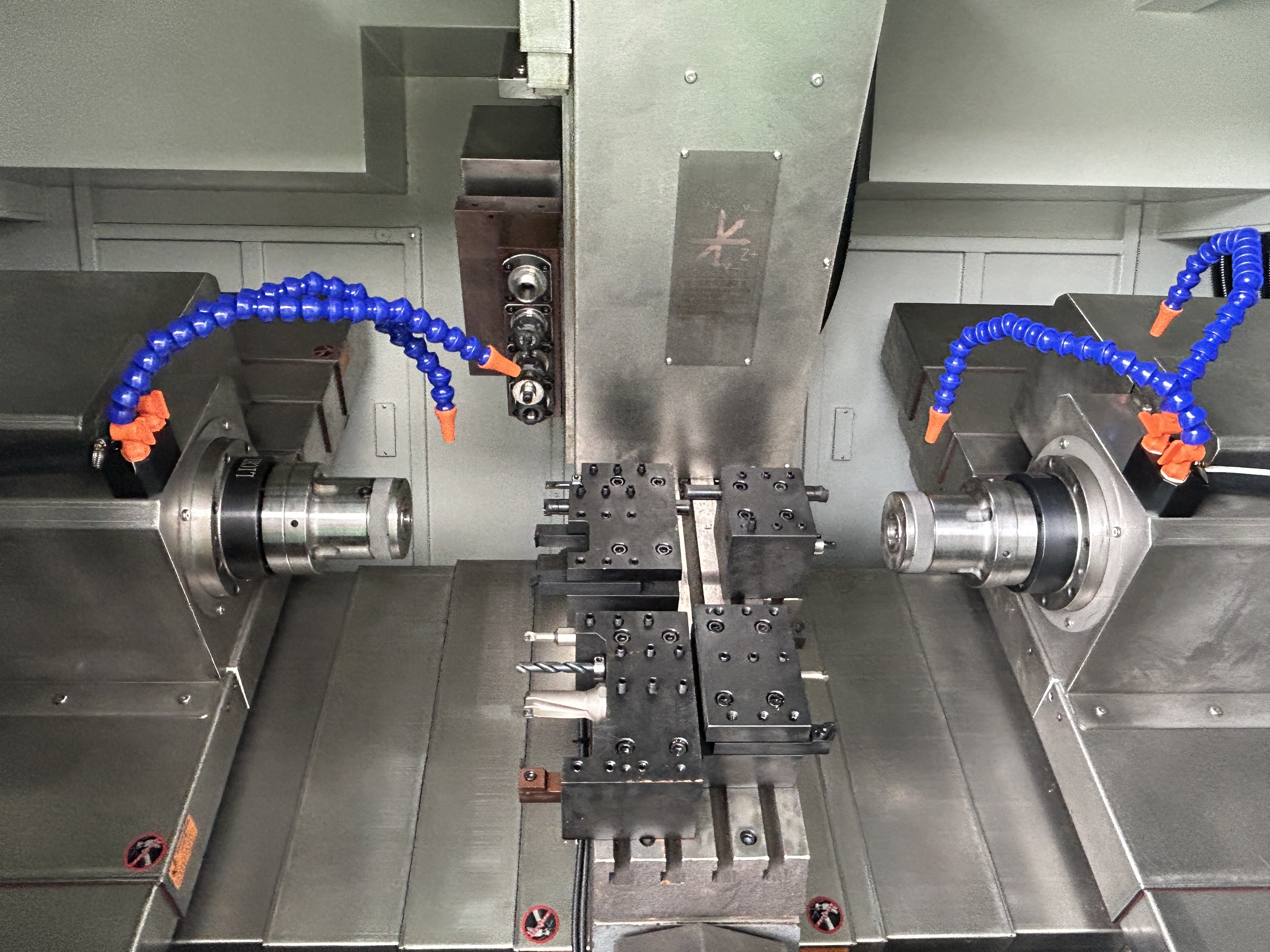

3. CNC Mill-Turn Center

Mill-turn centers combine the capabilities of lathes and mills, enabling the production of both rotational and prismatic parts in one setup.

Both the workpiece and tool can rotate, often in opposite directions. These machines support both turning and milling tools.

Capabilities

Reduces machine downtime and increases production speed.

Improved accuracy (up to 0.001”).

Superior surface finish with minimal irregularities.

Limitations

Less spindle freedom compared to dedicated milling machines.

Limited tool capacity for large cutters.

Applications

Highly complex parts: aircraft impellers, medical implants.

Automotive gears, engine valves, bearings.

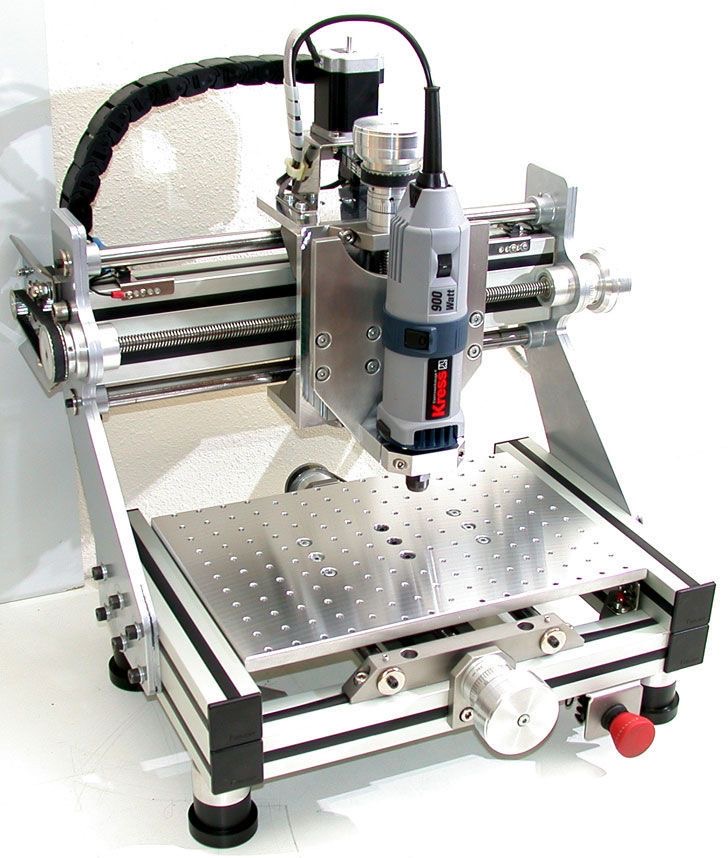

4. CNC Router

Routers operate similarly to CNC mills but are designed for softer materials and have limited Z-axis travel. A rotating tool moves along multiple axes.

Types include ATC (automatic tool change), nested, and industrial routers. Operations include contouring, engraving, threading, slotting, 3D carving, ramping, and facing.

Capabilities

High-speed machining of soft materials (wood, plastic, aluminum, rubber).

Reduced downtime with ATC.

Cost-effective for detailed and precise parts.

Limitations

Limited capability for deep holes and hard materials.

Noisy operation.

Applications

Sheet-based parts: signs, furniture, decorations.

Wood, metal, and plastic decorative items.

3D signage, logos, billboards.

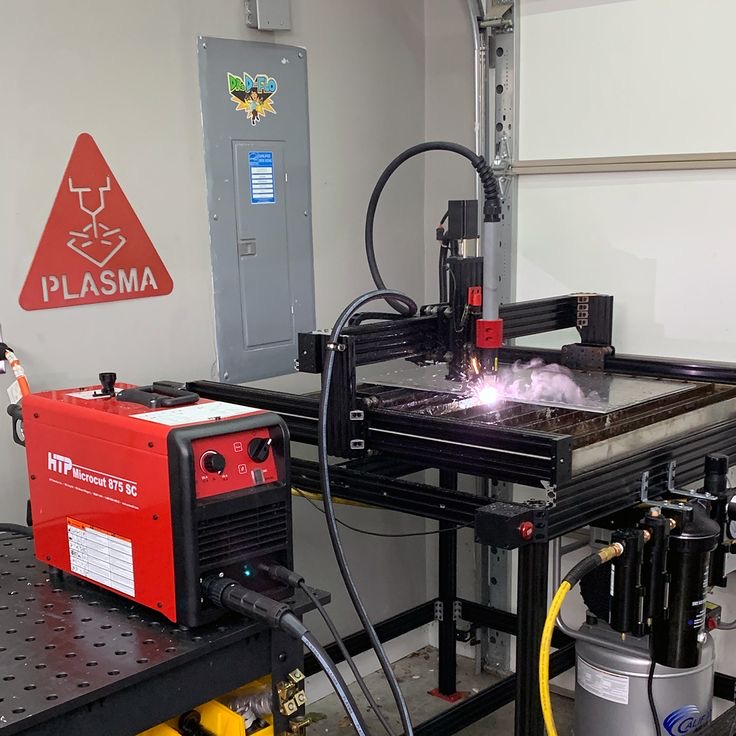

5. CNC Plasma Cutter

Plasma cutters use a high-temperature ionized gas stream (up to 40,000°F) to cut conductive materials. A CNC-controlled torch directs the plasma jet.

Capabilities

No mechanical stress on the workpiece.

Fast cutting speed with clean edges.

Suitable for irregular and curved shapes.

Limitations

Only cuts conductive materials.

Heat-affected zone may cause hardening.

Material thickness limited to 1–50 mm.

Applications

Sheet metal enclosures, pipes, brackets.

Structural supports, beams, panels.

Automotive body panels, frames, exhaust parts.

6. CNC Laser Cutter

Laser cuters use a focused high-energy beam for cutting and engraving with high precision. Types include CO₂, fiber, and Nd:YAG lasers.

Capabilities

Faster and more precise than plasma cutting.

Smooth finishes and fine details.

Cuts metals, plastics, and composites.

Limitations

Struggles with reflective materials like copper and brass.

Unsuitable for very thick materials.

Harmful fumes when processing plastics.

Applications

Etching, engraving, marking logos, signs, artwork.

Prototyping for automotive, aerospace, electronics.

Art, sculpture, furniture, cabinets.

7. CNC EDM Machine

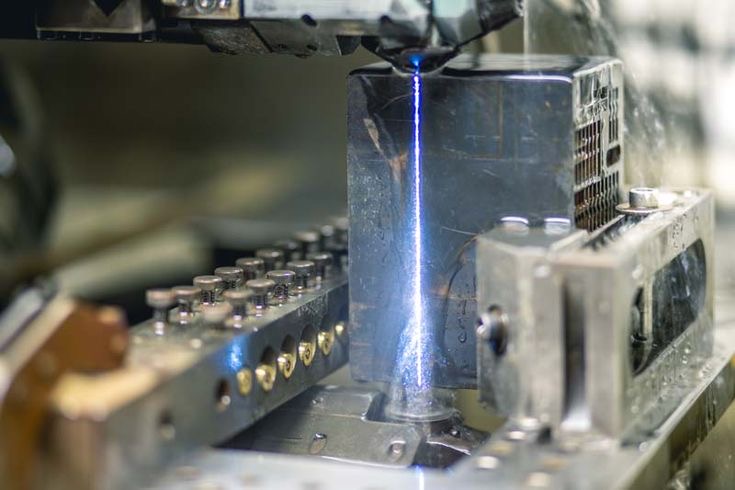

Electrical Discharge Machining uses sparks to erode material in a dielectric fluid. Types include wire, sinker, and hole-drilling EDM.

Capabilities

Produces complex features with high design freedom.

No mechanical stress.

Effective regardless of material hardness.

Limitations

Only processes conductive materials.

Slower than laser or plasma cutting.

High energy consumption.

Applications

Medical and dental implants, pacemakers.

Injection molds, casting dies, extrusion tools.

Electrical connectors, sensors.

8. CNC Waterjet Cutter

Waterjet machines use a high-pressure stream of water mixed with abrasive particles to cut materials. Pure waterjets cut soft materials; abrasive jets cut hard ones.

Capabilities

Cuts thick materials (up to 12 inches).

Compatible with composites, plastics, ceramics, foam.

No heat-affected zone.

Limitations

Slower than laser or plasma systems.

Risk of part failure under high pressure.

Lower accuracy compared to laser cutters.

Applications

Aerospace components: turbine blades, composites.

Seals, gaskets, gears.

Structural and architectural projects.

Stone carving, ceramic art, musical instruments.

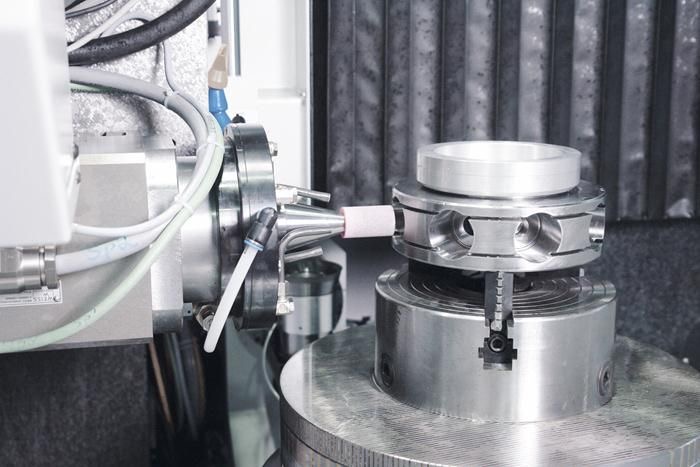

9. CNC Grinding Machine

Grinders use an abrasive wheel to achieve fine tolerances and smooth surface finishes. They can perform internal or external grinding.

Capabilities

Removes micro-cracks and surface imperfections.

Achieves tight tolerances with minimal material removal.

Rounds sharp edges and corners.

Limitations

Slow material removal rate.

Generates dust, debris, and noise.

Applications

Automotive parts: gears, brakes, bearings, crankshafts.

Medical devices and surgical instruments.

Tooling, molds, couplings.

10. CNC Drill Press

Drilling machines create precise cylindrical holes. Types include multi-spindle, radial arm, micro-drill, and screw machine drills.

Capabilities

Drills accurate holes in metals, plastics, composites.

Tight tolerances (as low as 0.001 mm).

Compatible with various drill bit types.

Limitations

Complex maintenance.

Limited hole diameter and depth.

Applications

Automotive, marine, and aerospace components.

Furniture and machinery manufacturing.

Assembly holes for rivets and fasteners.

Tapped holes for internal threading.

11. Multi-Axis CNC Machine

Machines with more than three axes (e.g., 4-axis, 5-axis, 6-axis) offer greater flexibility for complex geometries like deep slots, undercuts, and contours.

Capabilities

Complete complex parts in a single setup.

High speed and accuracy.

Simplified tooling and fixturing.

Limitations

High setup cost and requires skilled operators.

Complex programming increases error risk.

Applications

Precision parts for aerospace, medical, and defense.

Automotive engine blocks, cylinder heads, carburetors.

Jewelry, decorative items, furniture.

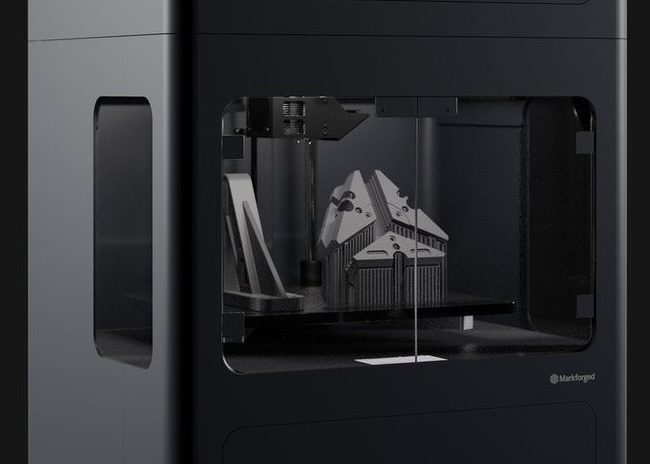

12. CNC 3D Printer

3D printers are additive manufacturing devices that build parts layer by layer. Common technologies include SLS, DMLS, SLA, and MJF.

Capabilities

High design freedom for complex geometries.

Minimal tooling requirements.

Reduced material waste.

Limitations

Limited material options (mainly plastics and some metals).

Post-processing required; not ideal for mass production.

Applications

Rapid prototyping and functional testing.

Enclosures for electronics, drones.

Custom medical implants and surgical guides.

Aerospace and spacecraft components.

Key Components of CNC Machines

All CNC machines include:

Bed: Rigid base for mounting workpieces.

Input Device: Uploads G and M code programs.

Machine Control Unit: Interprets programs and controls operations.

Display Unit: Shows real-time machining data.

Control Panel: Interface for operator input.

Machine Tool: Mechanical components including spindle, drives, and table.

Drive System: Positions the tool and workpiece via servo motors and lead screws.

Feedback System: Provides closed-loop control with sensors and transducers.

Chuck: Holds workpieces on lathes.

Headstock & Tailstock: Align and support the workpiece.

Foot Switch: Releases the chuck for unloading.

How to Choose the Right CNC Machine

Consider the following factors:

Material Type: Ensure machine compatibility with your workpiece material.

Part Complexity: Choose multi-axis or mill-turn machines for complex geometries.

Production Volume: High-volume production requires machines with ATC and high repeatability.

Accuracy Requirements: Select rigid machines like mill-turn centers for tight tolerances.

Part Size: Verify bed size and tool travel relative to your part dimensions.

Budget: Balance machine capabilities with cost, including operational expenses.

Conclusion

Selecting the right CNC machine depends on your specific material, design, volume, and precision requirements. Understanding these factors will help you make an informed decision that optimizes productivity and quality.

For more guidance or to explore our range of CNC machines, feel free to contact us!