Sep 13, 2025

Sep 13, 2025

287

287

admin

admin

A computer numerical control (CNC) lathe is a precision machining tool that rotates a workpiece on a spindle while a stationary cutting tool shapes the material by removing layers. Unlike manual lathes, CNC lathes are fully automated and follow programmed instructions—typically G-code—to execute highly accurate and repeatable operations.

It is often said that the lathe is the only truly universal machine tool because a lathe can produce all the parts needed for another lathe. This speaks to its fundamental role in manufacturing.

The workpiece is securely clamped in the spindle, which rotates at high speeds. The cutting tool, mounted on a turret, approaches the rotating material and systematically removes excess stock to achieve the desired shape. This process is known as turning.

CNC lathes operate along at least two primary axes:

X-axis: Controls the transverse movement of the tool (in and out).

Z-axis: Controls the longitudinal movement (back and forth).

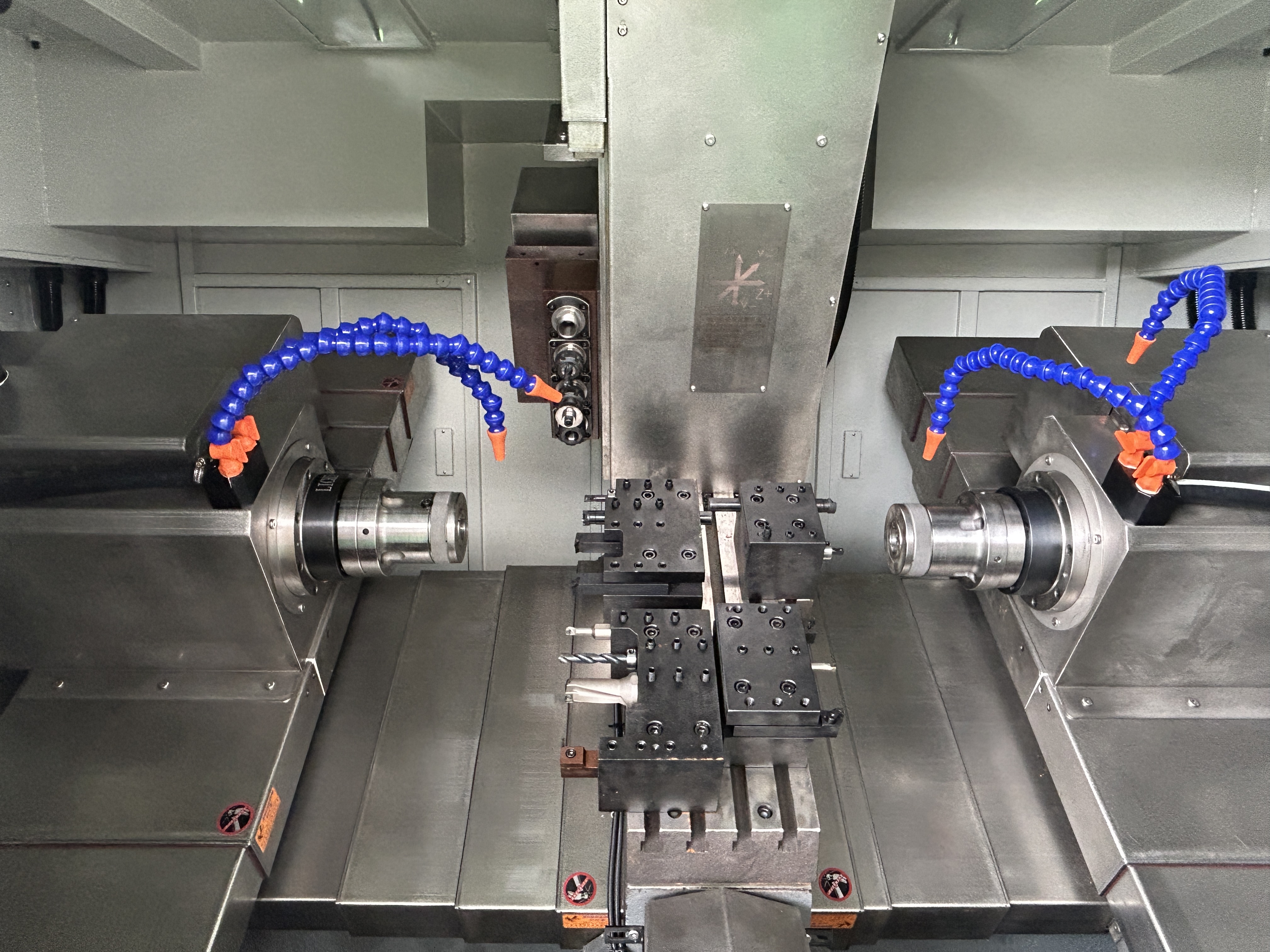

Advanced models may include additional axes (e.g., C-axis or Y-axis) and live tooling, enabling milling, drilling, and tapping operations without unclamping the part.

High Precision and Repeatability

CNC lathes deliver exceptional dimensional accuracy and consistency, making them ideal for high-volume production and complex part geometries.

Automation and Ease of Operation

Once programmed, CNC lathes require minimal manual intervention. Modern interfaces and CAD/CAM integration simplify setup and reduce operator training time.

Versatility in Tooling

Equipped with multi-station turrets, CNC lathes can hold numerous tools and automatically switch between them during operation. This allows for completing parts in a single setup.

Rigid Construction and Dynamics

Built with heavy-duty materials such as cast iron and equipped with precision ball screws, these machines ensure stability and dampen vibrations even at high cutting speeds.

Compatibility with Modern Tooling

CNC lathes are designed to utilize carbide inserts, CBN, and diamond tools, enabling the machining of hardened materials and exotic alloys.

CNC lathes are widely used across industries due to their ability to produce rotationally symmetric parts with high efficiency. Common applications include:

Automotive: Camshafts, crankshafts, bushings, axles

Aerospace: Nozzles, landing gear components, engine mounts

Medical: Implants, surgical instruments, prosthetics

Defense: Gun barrels, munition components, optical mounts

Consumer Goods: Baseball bats, furniture legs, musical instruments, decorative items

These machines can produce a wide range of features, including:

External and internal threading

Tapering and contouring

Grooving and parting

Drilling and boring

Knurling and polishing

Several specialized types of CNC lathes are available to meet specific production needs:

2-Axis Lathes: Standard models for straightforward turning operations.

Swiss-Type Lathes: Designed for high-precision, small-diameter parts using a sliding headstock and guide bushing.

Multi-Axis Turning Centers: Include additional axes and live tooling for complex milling and drilling.

Vertical Lathes: Suitable for large, heavy workpieces that are easier to load vertically.

CNC lathes offer significant advantages over traditional engine lathes:

Faster Production Times: Reduced cycle times and automated tool changes increase throughput.

Improved Accuracy: Digital control eliminates human error.

Flexibility: Quick changeovers between jobs through program uploads.

Labor Savings: One operator can manage multiple machines.

Complex Geometries: Capable of producing shapes that are impractical or impossible manually.

CNC lathes represent the backbone of modern subtractive manufacturing. Their precision, speed, and flexibility make them indispensable in industries requiring high-quality round parts. Whether you are prototyping or engaged in large-scale production, integrating a CNC lathe into your workflow can significantly enhance capability and efficiency.

At Lichi Machinery, we offer a range of CNC lathes suited to various applications—from entry-level to advanced multi-tasking systems. Contact us today to learn how our solutions can help you achieve your manufacturing goals.