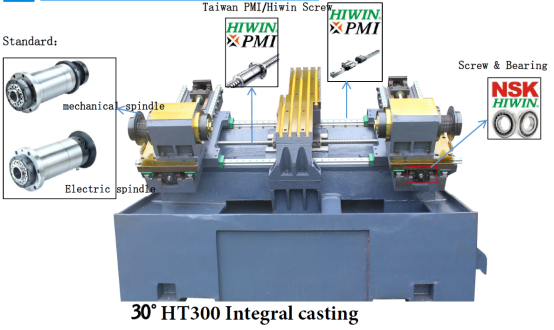

Features of the machine tool: one-piece 30° inclined bed casting base, double spindle, double channel, butt joint structure, designed and developed for bar products, stainless steel full protective sheet metal, more waterproof and chip-proof, and can be equipped with a power head to complete complex workpieces Processing, higher efficiency.

This machine adopts a rectangular one-piece casting 30° bed, and the inclined bed design makes the distance between the turning tool and the workpiece more stable when it is fed, which can effectively reduce vibration and noise, and improve precision and processing speed. Precision quill spindle, driven by servo motor.

The new appearance design increases the opening of the safety door to make the operation more convenient and improve the workability. The enlarged observation window also improves the visual effect in the processing room. By enlarging the cutting drop opening and the chip outlet close to the outer end of the housing, it is easy to clean up the waste. The latest NC device - double check as a standard function improves safety and productivity.

The bed, which is the key element of processing, inherits the traditional one-piece bed structure. Increased weight while increasing size improves shock absorption. In addition, the thermal displacement stability is improved by increasing the capacity of the cutting fluid tank, which greatly improves the overall rigidity of the machine tool; the casting materials are all made of high-quality HT300 brand cast iron, which has excellent stability after secondary aging and tempering treatment.

The LC type has a mechanical structure of double spindles and double row cutters, which further improves the basic performance by increasing the rigidity of the bed and row cutters.

The newly designed bed has high rigidity while increasing the weight. All guide rails adopt scraping-type square guide rails, which increase the contact area of the sliding surface, thereby further improving rigidity and shock absorption, realizing powerful cutting, and increasing the service life of cutting tools.

Feed mechanism: Both X-axis and double Z-axis adopt Taiwan PMI (standard configuration) R3210 specification C3-level precision precision screw rod, and are equipped with high-precision bearings with special angular contact for screw rod automatic positioning; Z-axis and X-axis respectively adopt Taiwan 30 specification P2-level precision HiWim linear guide rails ensure the precise movement of the machine tool and create machining accuracy.