LC-LX52SDY inclined bed double spindle double live tool turret, adopts 30 degree inclined bed and frame integrated design. Channel one spindle is fixed, equipped with Taiwan TCSM BMT45, 12 stations with Y axis turret for processing, Channel two is equipped with Taiwan TCSM BMT45, 12 stations with Y axis turret, fixed in the direction of channel one spindle, and the part is processed by moving the spindle.

This machine tool is a CNC turning and milling compound lathe integrating high performance, high precision, high efficiency and high rigidity. Its structural form is that the two spindles are arranged in parallel and opposite, and the program can be written independently for channel one and channel two to control the movement of X1 axis Z1 axis and X2 axis Z2 axis, so as to realize the automatic docking and exchange of the workpiece clamped by the spindle and the sub-spindle, and work at the same time, which solves the problem of processing the two processes of the clamping end of the workpiece under one clamping. It is suitable for complex products that need two processes later and need turning and milling in two clampings, so as to realize one clamping and two processes at the same time.

The double X-axis and double Z-axis both use Taiwan PMI (standard) R3210 specification C3 grade precision screws, and are equipped with high-precision bearings for screw-specific angular contact automatic positioning; the double Z-axis and double X-axis use Taiwan Hiwin or PMI 45 and 35 specifications P2 grade precision roller linear guides respectively to ensure the precision movement of the machine tool and create processing accuracy.

The machine tool can integrate various forms of loading and unloading, realize automated production, achieve small footprint, save labor and other advantages.

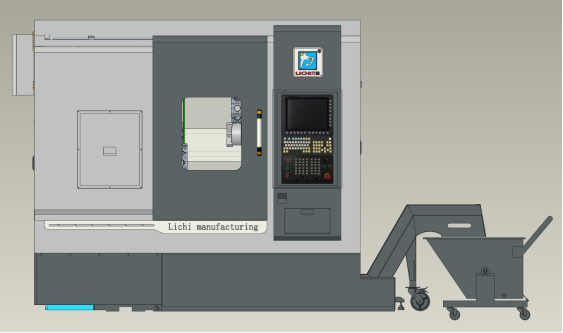

Image examples:

![1750385479656048.png 67O]R1L[6~8QI3PR3[(@7SS.png](/uploads/ueditor/image/1750385479656048.png)

Slant bed double spindle double live tool turret CNC lathe

![1750385507283555.png F6YC39KXMH~]){OKFPLBR3W.png](/uploads/ueditor/image/1750385507283555.png)

Slant bed double spindle double turret (one live tool spindle and one servo turret)

CNC lathe

The CNC machine tool with chip conveyor