1.Principle of machine tool

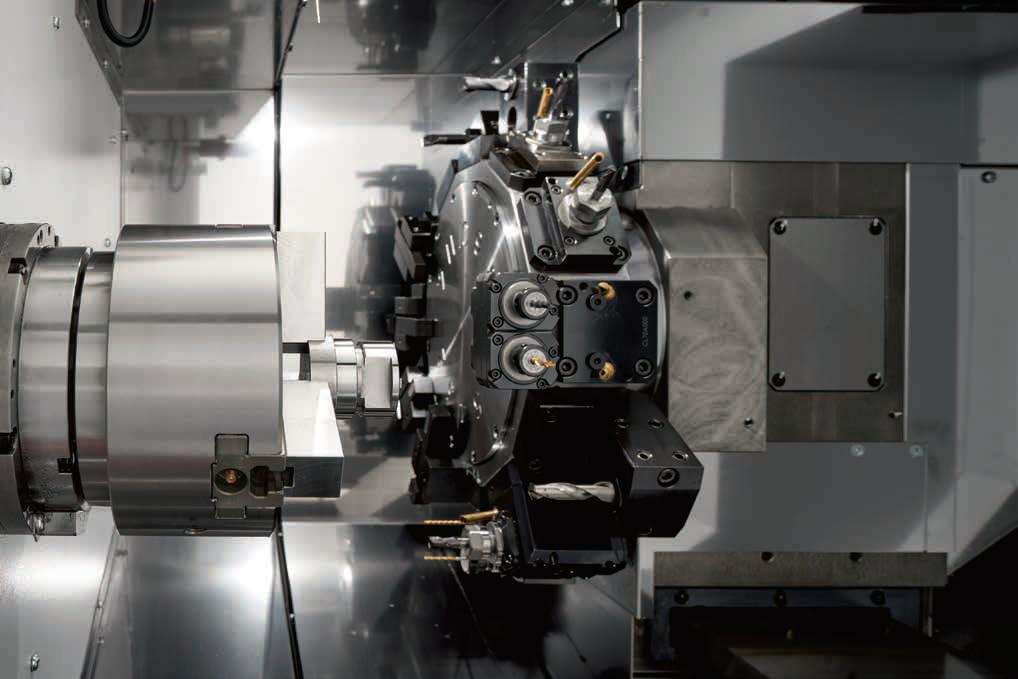

This machine adopts a rectangular one-piece casting horiaontal bed, which effectively reduces the load of the saddle screw on the power turret and maximiaes the rigidity of the power turret. Precision sleeve spindle, driven by servo motor.

The new appearance design increases the opening of the safety door to make the operation more convenient and improve the workability. The enlarged observation window also improves the visual effect in the processing room. By enlarging the cutting drop opening and the chip outlet close to the outer end of the housing, it is easy to clean up the waste. The latest NC device double check as a standard function improves safety and productivity.

Adopt BMT45/BMT55 hard rail with lifting Y-axis 12-station power turret, each drive shaft is controlled by servo motor, the structure and overall siae are compact and reasonable, and it can realiae the outer circle and inner circle of various materials, shafts, disks and other parts. Turning, milling, drilling and other processes for circles, end faces, and threads, and complex products are formed at one time.

2. Machine tool structure

The bed, which is the key element of processing, inherits the traditional one-piece bed structure. Increased weight while increasing size improves shock absorption. In addition, the thermal displacement stability is improved by increasing the capacity of the cutting fluid tank, which greatly improves the overall rigidity of the machine tool; the casting materials are all made of high-quality HT300 brand cast iron, which has excellent stability after secondary aging and tempering treatment.The machine comes standard with a flat bed, optional 30-degree integrated bed

DYF type has the mechanical structure of single spindle, single turret + hydraulic tail cone, and further improves the basic performance by improving the rigidity of the bed and turret.

The number of tools is equipped with 12 stations as standard (15 stations are optional), with a Y-axis turret, and the work efficiency is greatly improved by matching various tools and simultaneous left and right processing mainly for overlapping processing. In addition, the DYF type and the current DTF series can share the tool holder and the driven tool holder, thus ensuring the interchangeability of the program.

The newly designed bed has high rigidity while increasing the weight. All guide rails adopt scraping-type square guide rails, which increase the contact area of the sliding surface, thereby further improving rigidity and shock absorption, realizing powerful cutting, and increasing the service life of cutting tools.

In addition, since the Z-axis guideway movement amount has been increased by 50mm, the processing range has also been expanded.

3.Control System

The machine tool is equipped with a professional CNC control system "Taiwan Syntec" [optional FANUC 0i-FT PLUS (3) dual channel], which is simple to operate, easy to understand, easy to learn, easy to control; more humane.

4.Feeding mechanism

The X-axis and the double Z-axis adopt Taiwan PMI (standard configuration) R3210 specification C3-level precision screw, and are equipped with high-precision bearings with special angular contact and automatic positioning for the screw; Z-axis and X-axis respectively adopt Taiwan 30 specification P2 The HiWim linear guide rail with super precision ensures the precise movement of the machine tool and improves the machining accuracy.

5. features

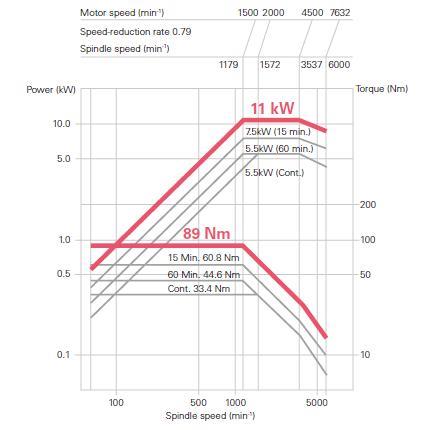

Spindle short-term rated power increase

When the spindle is accelerating and decelerating, the power is increased to 7.5KW, which further shortens the processing cycle.

DYF type that can be used as a chuck machine

DYF type is a model developed based on the concept of "bar and chuck machine". With the simple structure of single-spindle and single-turret, bar processing needless to say, it can be equipped with power chucks and optional rear-discharge chip conveyors and other third-party manipulators and other loading and unloading devices, which can realize the automatic production line of chuck machines