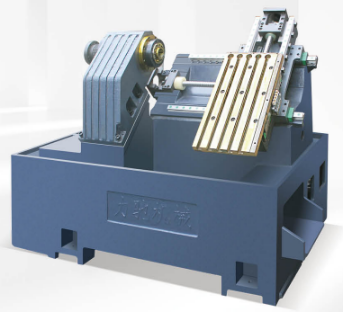

1.The integral high-strength cast iron bed HT300 is cast by resin sand by a professional foundry manufacturer. It adopts a 40-degree inclined bed structure, which has sufficient rigidity, good vibration absorption and thermal stability, and adopts wide-span Taiwan linear guide rails or German linear guide rails. , the machine tool bears a large load, has good dynamic response, eliminates low-speed crawling, and has good precision retention. This machine tool has high rigidity, precise positioning, high speed and high efficiency

![1750384889124987.png LAPSH_LQM9UKKL5SE9LR]VG.png](/uploads/ueditor/image/1750384889124987.png)

2.Features

Automatic lubrication: reduce frictional resistance, absorb heat, improve guide rail precision, prolong guide rail life, shock absorption, anti-corrosion;

Three-color light: indicates the running state, standby state, fault state, etc. of the machine tool, which is convenient for the operator to judge and diagnose the state of the machine tool in time, reduces misoperation and waiting time, and improves work efficiency

Cooling system: High-pressure chip breaking and punching to avoid iron filings winding; a good and reliable cooling method can improve tool life and cutting parameters, thereby improving production efficiency and effectively improving machine tool startup rate

Especially for: heat-sensitive low-melting point materials (aluminum, magnesium, aluminum-magnesium alloys, pure aluminum, aluminum alloys, aluminum alloy casting materials, high-silicon aluminum alloys)

Viscous materials, springback, extrusion, built-up edge, wear resistance and cutting hardening of materials with relatively high elastic modulus (nickel alloys, stainless steel, etc.).

Work lights: Machine tool work lights can provide machine operators with a clear lighting environment, enabling them to detect quality problems of workpieces in time, improve product quality, and increase production efficiency

Heat exchanger: Transfer the high-temperature heat inside the machine tool to the outside for heat dissipation, and introduce the external low-temperature medium into the machine tool for heat dissipation, improving processing efficiency and product quality、

Foot switch: a safety protection device, which can conveniently control the forward and reverse rotation, start and stop of the lathe, making the operation more flexible and convenient, and can effectively protect the safety of the operator

The X-axis and Z-axis both adopt Taiwan roller/ball type 30 linear guides and 3210 high-precision screw rods to enhance the rigidity of the machine tool and improve the precision of the machine tool. With automatic forced lubrication, the high-speed movement of the machine tool is realized and the positioning accuracy of the machine tool is ensured.