Description of functions and features:

1. Machine working principle

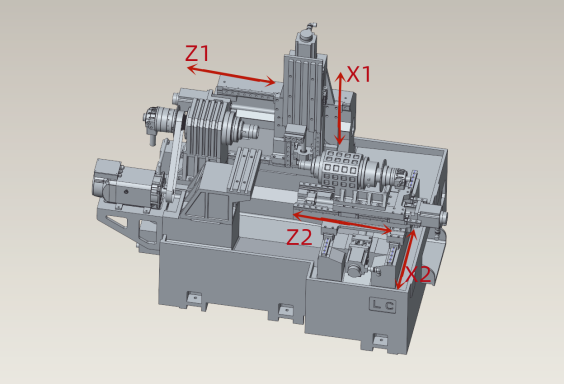

The machine tool adopts a two-way docking spindle structure. The left mechanism is named "Axis 1" and the right mechanism is named "Axis 2".

The axis 1 is placed behind the left side, the Z axis moves left and right, the X axis moves up and down, and the spindle is fixedly installed on the left frame.

The axis 2 is placed on the right side. The Z axis moves left and right and is parallel to axis 1. The X axis moves forward and backward. The spindle mechanism is installed on the moving carriage and can be accurately docked with axis 1.

The mechanisms of Axis 1 and Axis 2 operate independently, allowing Axis 1 and Axis 2 to flexibly execute dual-channel driver processing.

2. Machine tool structure

The overall castings are made of HT300 high-quality cast iron, which has undergone secondary aging and tempering treatment, resulting in less deformation and excellent rigidity.

3. Control system

The machine tool is equipped with a "dual-channel" control system and single-interface operation, which is simple, easy to understand, easy to learn, and easy to control.

4. Feeding mechanism

The X-axis and Z-axis both use Taiwanese brand P-level precision ball linear guides and C3-level precision precision screws; they are also equipped with special angular contact type, automatic positioning high-precision bearings for the screws to ensure the precision of the entire machine's sliding mechanism. move.

Good performance and strong stability

Because of dual-spindle design, it has very reliable advantages in terms of fast moving speed, high processing efficiency, and guaranteed processing accuracy. The overall workflow performance is stable and safe. Avoid unexpected failures at work.

Modular design

The CNC double-spindle lathe adopts a modular design, which ensures that it can meet the needs of different environmental situations during work. It can be customized and produced according to the needs of the working environment, and it is simpler and more convenient to maintain and effectively reducing use and maintenance cost.

Provide different types of configurations

CNC double-spindle lathes meet the needs of a variety of environments. In addition to the performance advantages and reliability, it can also provide a variety of different configurations according to the needs of the working environment. It is suitable for various environmental fields and has particularly strong applicability. If you choose regular brand products, you will get good advantages in terms of application functions.